As electric vehicles transition from niche innovation to a core pillar of global transportation, expectations for battery performance have risen sharply. Today’s drivers no longer view range as the sole measure of a capable EV. They expect consistent performance in harsh climates, rock-solid safety in everyday use and emergencies, and battery systems that can remain reliable for years of intensive driving. In this shift toward higher standards, BYD’s Blade Battery has become one of the most transformative developments in the industry.

First introduced in 2020, the Blade Battery reimagines lithium iron phosphate (LFP) technology from the ground up. Instead of working within the conventional constraints of modular pack architecture, BYD re-engineered both the cell format and the internal structure of the entire battery pack. The result is a system that delivers exceptional thermal stability, superior space efficiency, and the safety characteristics for which BYD is now widely recognized. Over the past several years, the Blade Battery has earned its place as one of the safest and most durable EV battery technologies in mass production.

A Structural Redesign That Changes Everything

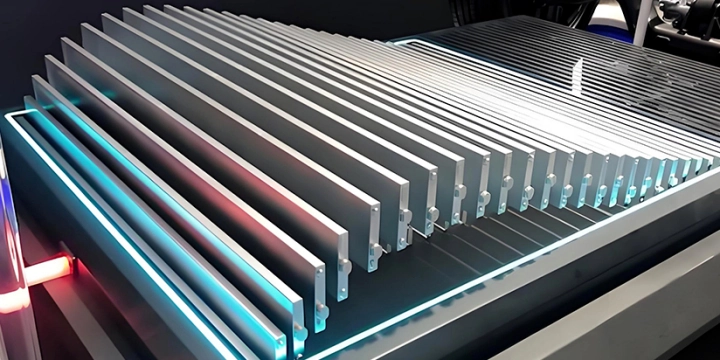

The defining feature of the Blade Battery is its distinctive long-cell structure. Each cell is designed in a slim, elongated format that resembles a blade—hence its name. This geometry allows the cells to occupy significantly more of the pack’s internal volume compared with traditional prismatic LFP cells, which typically suffer from lower space utilization due to their shape and the need for module housings.

By optimizing the shape and minimizing structural redundancy, BYD increases pack-level space utilization from roughly 40–50% in conventional LFP systems to more than 60%. This improvement means that more active material can be packed into the same physical footprint, directly contributing to greater energy efficiency.

However, the true breakthrough comes from BYD’s cell-to-pack (CTP) integration. Instead of grouping cells into modules, the long blade-shaped cells are arranged directly within the pack structure, standing upright like books on a shelf. This eliminates unnecessary module hardware and creates a mechanically reinforced, highly compact array.

This approach offers three major engineering advantages:

1. Higher volumetric efficiency

The pack stores more energy without increasing its external dimensions, enabling competitive driving ranges even with LFP chemistry.

2. Improved structural rigidity

Because the cells act as load-bearing members, the pack gains inherent mechanical strength. This enhances crash resistance and contributes to vehicle chassis stability.

3. Better thermal regulation

The slim cells provide a large surface area for heat transfer, allowing the thermal management system to regulate temperatures more quickly and evenly.

Together, these characteristics form a structural concept that differs fundamentally from traditional LFP systems and sets a new benchmark for pack-level engineering.

Safety as the Foundation

Safety remains the central criterion for battery design. Incidents involving thermal runaway—where a battery cell rapidly overheats—have drawn global attention to the risks of unstable battery chemistries or inadequate pack engineering. The Blade Battery was developed specifically to address this challenge.

The use of LFP chemistry already provides a significant advantage. LFP materials have a more stable molecular structure and a higher decomposition temperature than nickel-rich chemistries such as NCM. But BYD’s safety performance is not solely the result of materials—it stems from the combination of chemistry, cell format, and pack architecture.

The elongated cells enhance heat dissipation, and the dense, uniform pack structure limits the possibility of heat propagation from one cell to another. Even under extreme abuse tests, the Blade Battery demonstrates exceptional thermal resilience.

Key safety achievements include:

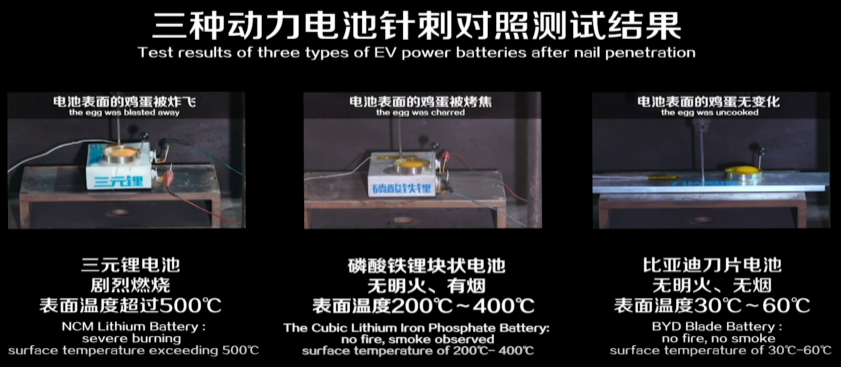

• Nail penetration test performance

Regarded as the most stringent test for evaluating thermal runaway, the Blade Battery remains stable without smoke or fire even under direct puncture—an outcome that many NCM and standard LFP cells fail to achieve.

• High-temperature tolerance

Blade cells remain thermally stable at temperatures where other chemistries begin to decompose or emit gases.

• Crash and extrusion resistance

Because the pack’s internal structure is mechanically reinforced by the rigid blade cells, it offers higher resistance to deformation during collisions.

• Overcharge safety margin

Even under severe electrical abuse, the Blade Battery maintains controlled behavior without entering runaway conditions.

These attributes make the Blade Battery especially appealing in global markets that emphasize reliability and strict safety certification, including Europe, the Middle East, Southeast Asia, and Latin America.

Longer Service Life and Lower Degradation

A long-lasting battery is essential not only for consumers but also for fleets, government vehicles, and ride-hailing applications where high mileage is common. LFP chemistry is known for longevity, but the Blade Battery’s architecture further extends its usable life.

Because the cells operate under more uniform temperatures and lower internal stress, the battery exhibits:

- Excellent cycle life over many years of daily use

- Slower degradation even in hot climates

- Stable capacity retention under heavy load conditions

For high-mileage users, this translates into a lower total cost of ownership, greater predictability, and confidence that performance will remain consistent over long operating cycles.

Reliable Performance in Extreme Climates

Battery behavior is highly sensitive to temperature, making thermal management one of the most critical factors in EV design. The Blade Battery’s slim-cell format significantly improves heat transfer efficiency, enabling the thermal management system to react quickly to both cooling and heating demands.

The result is consistent performance across diverse environmental conditions:

- Faster and more stable fast-charging

- Reduced risk of localized hot spots

- Stronger winter performance, including lower capacity fade in cold climates

These attributes support BYD’s international expansion, ensuring that vehicles powered by the Blade Battery remain reliable whether they operate in desert heat, tropical humidity, or northern winter conditions.

Designed for Diverse Vehicle Platforms

In addition to powering BYD’s electric passenger cars, the Blade Battery has become a versatile energy platform adopted across multiple vehicle categories.

It is used widely in:

- BYD’s DM-i super hybrid lineup

- Pure electric vehicles within the Ocean and Dynasty series

- Light commercial vehicles and buses

- Partner OEMs leveraging BYD’s battery technology

Its modular manufacturing flexibility allows BYD to adapt pack dimensions, cooling layouts, and energy configurations to suit everything from compact sedans to full-size SUVs and commercial fleets.

Sustainability Built Into the System

Sustainability has become inseparable from modern battery development. The Blade Battery aligns naturally with global decarbonization goals thanks to both its chemistry and its manufacturing ecosystem.

- LFP chemistry avoids nickel and cobalt, reducing dependence on materials linked to higher mining impact.

- BYD’s vertically integrated supply chain—from cathode materials to cell and pack production—ensures consistent quality control and lowers energy consumption during manufacturing.

- The long service life of the Blade Battery reduces environmental burden by extending the replacement cycle.

As countries accelerate their transition toward clean mobility, the Blade Battery offers a responsible and scalable energy solution that aligns with future sustainability standards.

Conclusion: Setting a New Standard for EV Battery Technology

The BYD Blade Battery represents far more than an incremental improvement. It reflects a complete rethinking of how an electric vehicle battery should be engineered—prioritizing safety, structural efficiency, thermal stability, and long-term durability. As global markets demand increasingly responsible and dependable EV technologies, the Blade Battery stands as one of the most proven and mature systems available today.

With its unique combination of safety leadership, robust performance, and sustainable design, the Blade Battery continues to shape the future of electric mobility and supports the broader transition toward a cleaner, more secure energy landscape.