When people talk about electric vehicles, battery capacity and driving range usually take center stage. But behind every efficient and long-lasting battery is a sophisticated control system working quietly in the background — ensuring safety, maximizing performance, and extending battery lifespan. This control powerhouse is the Battery Management System, commonly known as the BMS.

For BYD, one of the world’s top new energy vehicle manufacturers and a global leader in power battery innovation, BMS technology is not an accessory — it is a critical part of the company’s engineering philosophy. From the well-known Blade Battery to DM-i hybrid systems and the latest high-voltage EV platforms, BYD’s BMS guarantees that every kilowatt-hour of energy is used safely and wisely.

1. What the BMS Does: The Battery’s Guardian and Decision-Maker

A modern traction battery is more than a simple energy container. It is a complex assembly of hundreds of lithium-ion cells that must work together flawlessly. Even a slight imbalance between them can impact performance or create safety risks.

The BMS is responsible for constant, real-time supervision of this system — like the battery’s central nervous system.

Key monitoring functions include:

- Voltage management — Each cell’s voltage is tracked to prevent overcharge or over-discharge

- Current control — Regulates charging and discharging loads based on real-time conditions

- Temperature monitoring — Ensures thermal stability across all cells

- SOC (State of Charge) estimation — Calculates usable battery range accurately

- SOH (State of Health) calculation — Predicts long-term battery performance and aging

In simple terms, if a battery is the heart of the EV, then BMS is the brain.

2. Safety First: The Core Principle of BYD BMS

Battery safety is an uncompromised requirement, especially for global electric mobility expansion. BYD’s BMS incorporates multiple layers of protection:

Thermal Safety Management

- Real-time temperature sampling across dozens of sensing points

- Early-warning algorithms for abnormal heat rise

- Intelligent emergency mitigation: current limiting, cooling activation, system isolation

Cell Equalization

Lithium cells age differently over time. BYD uses both active and passive equalization strategies to balance cells and maintain consistent performance within the pack.

Fault Diagnosis & Predictive Safety

The BMS continuously evaluates patterns in voltage drift, resistance changes, and localized temperature spikes to predict potential risks long before they escalate.

These features reinforce the inherent safety advantage of BYD’s LFP Blade Battery, which already delivers exceptional resistance to thermal runaway.

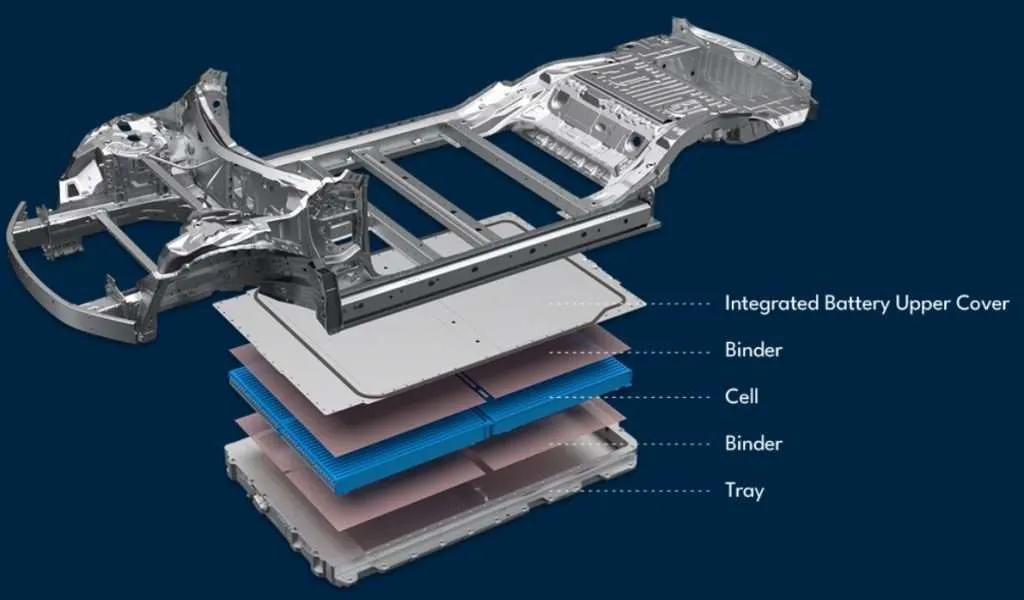

3. Deep Integration with the Blade Battery

Since 2020, the Blade Battery has been widely recognized as one of the safest power battery systems used in global EVs. Yet much of its safety and stability depends on its intelligent BMS coordination.

The Blade Battery + BMS =

- Higher usable energy due to precise SOC calibration

- Better stability in extreme climates

- Longer lifecycle, even under high-frequency charge/discharge loads

- Structural protection + intelligent monitoring for real-time safety control

This level of co-design is only possible because BYD is vertically integrated — developing both battery chemistry and electronic intelligence under one roof.

4. Efficiency and Range Management: More Miles per kWh

Beyond safety, BYD’s BMS enhances driving efficiency through dynamic energy control:

- High-accuracy SOC improves range prediction confidence

- Temperature-aware charging protects lithium activity and shortens fast-charge time

- Optimized discharge patterns support higher motor efficiency

For example, BYD EVs maintain high usable energy ratio across different climates, while many competitors lose significant range in cold temperatures.

Result: Drivers enjoy longer real-world mileage and more consistent performance.

5. Communication and Power Distribution: A Team Effort

BYD BMS works collaboratively with the motor control unit (MCU), vehicle control unit (VCU), and thermal control system to coordinate power delivery.

Key communication functions

- High-speed CAN and Ethernet networks

- Cell-level data fusion to inform vehicle power requests

- Load-balanced planning for acceleration, hill climbs, and regenerative braking

A sudden acceleration requires instant high current — BMS determines if the power is safe to provide. When descending a steep hill, regenerative braking charges the battery — BMS controls the current to avoid over-voltage risk.

The system continuously negotiates between performance and longevity.

6. BYD vs. Industry: Why BMS Expertise Matters

Not all EV makers design their own BMS — many outsource solutions from suppliers. BYD’s independent R&D enables more precise coordination and faster innovation cycles.

Here’s a comparative overview:

| Capability | BYD BMS | Tesla | Legacy OEMs (Generalized) |

| Battery + BMS Co-Design | ✔ Fully integrated | ✔ Strong | ❌ Often separated |

| LFP Optimization | ✔ Industry leading | Moderate | Limited |

| Safety Margin | Very high | High | Varies |

| Predictive Diagnostics | ✔ Advanced | ✔ Advanced | Medium |

| Global Deployment Scale | ✔ Large and diverse | Large | Moderate |

Conclusion: BYD excels particularly in mass-market LFP safety and climate stability, while matching global leaders in high-performance EV intelligence.

7. Built for Tomorrow: OTA Upgrades & Global Adaptation

As battery technology evolves, so does the BMS. BYD implements:

- OTA updates for continuous feature and safety improvements

- Regional calibration for:

- Charging infrastructure differences

- Climate and altitude variations

- Market-specific safety regulations

The BMS evolves alongside the vehicle, rather than becoming outdated the day it rolls off the production line.

Conclusion: Quiet Intelligence with a Powerful Role

Car buyers rarely think about the BMS — and that’s exactly how it should be. It operates silently, constantly working to keep the battery:

- Safe

- Efficient

- Long-lasting

- Confident in every drive

As the global transition to electrification accelerates, BYD’s mastery of both battery chemistry and battery intelligence gives the company a crucial advantage. The Blade Battery may be the star on paper, but the BMS is the unsung engineer making every journey safer and every charge more meaningful.

In the world of EVs, smart power isn’t just energy — it’s intelligent energy.

BYD’s BMS ensures that intelligence is felt, every day, by millions of drivers around the world.